B2B offer

Business Cooperation

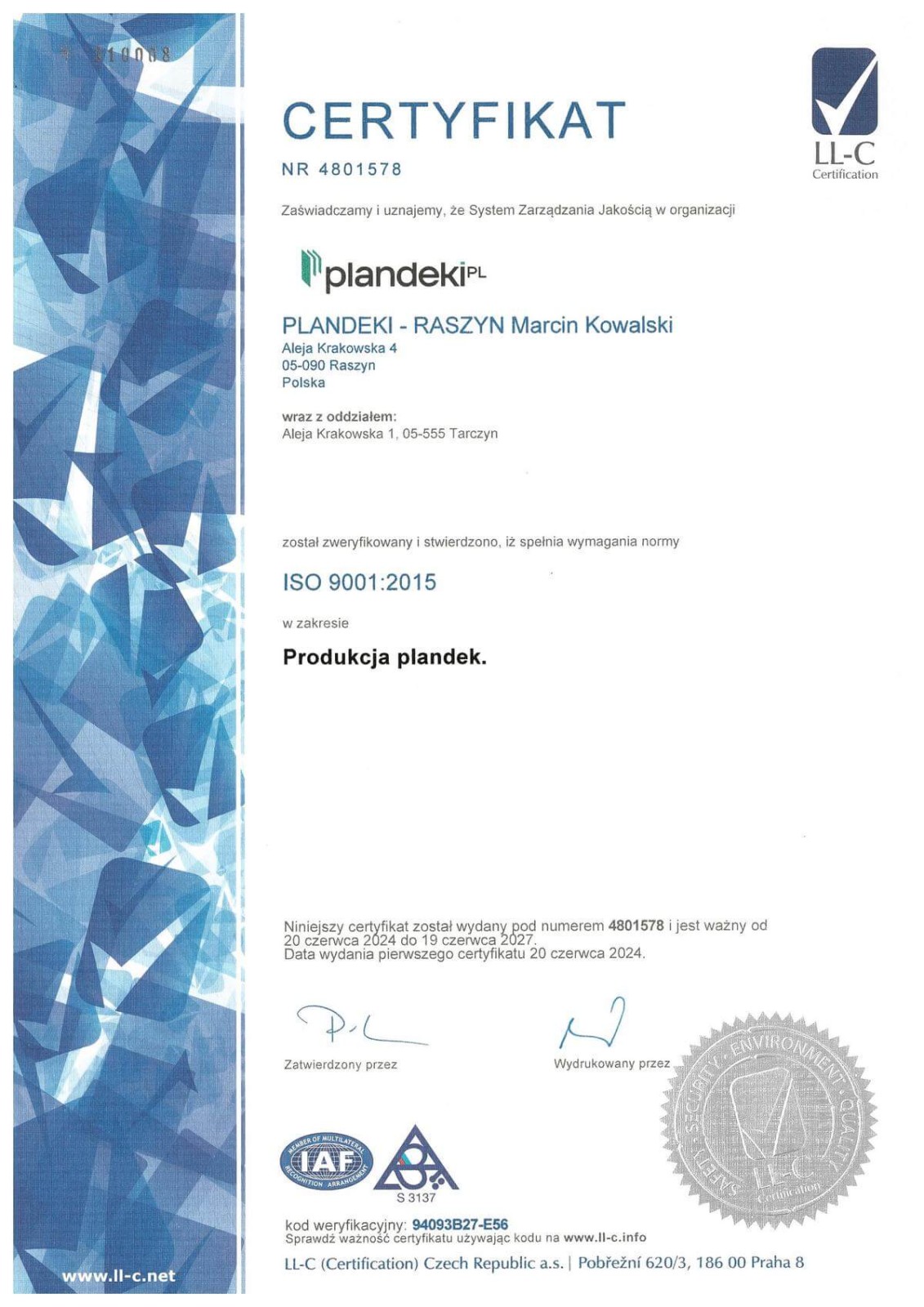

We specialize in the serial production of PVC tarpaulins for external companies, offering comprehensive support at every stage of cooperation along with the highest standards of quality and punctuality.

Our extensive machine park and large production halls enable us to handle large-scale orders. Each business partner receives a dedicated account manager who oversees the entire order process. We manufacture based on provided technical documentation, with full respect for the client’s brand identity and specifications. We operate in OEM (Original Equipment Manufacturer), ODM (Original Design Manufacturer), and white label models – offering unbranded production, co-developed and optimized together with the client, ready for distribution under their brand. Thanks to our flexible approach, high efficiency, and advanced technologies, we are a reliable partner for both large enterprises and dynamic brands expanding their product portfolios.

Feel free to contact us – we will be happy to prepare an offer tailored to your company’s needs.

Company Branches

We have four production plants near Warsaw, with a total production hall area of 4,000 m², enabling us to fulfill large-volume orders on tight schedules. Our main production facility is located in Tarczyn – a convenient location near a national road that facilitates transportation and logistics for wholesale orders. An additional advantage is the proximity of Warsaw’s international airport – just a 20-minute drive away – which facilities the organization of in-person meetings and short, one-day business visits.

In Raszyn, we have a branch dedicated to individual clients, where we handle custom and non-standard orders. Two additional facilities in the region support serial production, ensuring continuity and on-time deliveries.

production divisions

of production hall space

High-Frequency Welders

Our plants are equipped with modern high-frequency welders which ensure precise and durable welding of PVC fabrics. We have a total of 14 machines operating on special tables with a combined length of 227 meters, allowing for uninterrupted large-scale production. Thanks to the longest tables, we can produce coverings up to 60 meters in length. This extensive machine park enables continuous and efficient production regardless of project complexity. We specialize in manufacturing large-format coverings, meaning no dimensions are too big – we undertake on even the most demanding jobs.

high-frequency welding machines

workbenches

Manual Welders

We also have a large fleet of handheld and self-propelled hot air welders as well as ultrasonic manual welders. They allow for precise joining of PVC fabric panels before processing with high-frequency machines and for creating unusual or hard-to-reach details. This ensures high flexibility in production.

hot air welding machines

ultrasonic welding machine

Sewing Machines

In our plants, we use 16 specialized sewing machines, including double-needle and automatic machines that ensure precision and repeatability. We have a dedicated team of stitchers who continually work on components, adapting them for further production stages.

sewing machines

professional team of seamstresses

PVC Plotters

All orders are cut using modern PVC plotters. We have 2 machines running 24 hours a day, 6 days a week. These machines allow us to cut nearly any shape designed in CAD software.

PVC Plotters

efficient 24/6 operation

Employees

At Plandeki.pl, we employ over 80 production workers organized into 15 specialized teams working in a three-shift system, allowing us to efficiently and reliably fulfill even the largest orders. At the same time, our success would not be possible without the dedication of colleagues from other departments – logistics, customer service, quality control, technical office, and administration – who support production and keep the company running smoothly every day. We are a well-coordinated team working together to deliver quality, punctuality, and customer satisfaction.

more than 80 production workers

quality control department

Technical Support

Our technical department includes 10 specialists responsible for consulting, preparing documentation, and optimizing the production process.

specialists

optimization of production processes

Warehouse Space

We have 3,200 m² of warehouse space, allowing for efficient storage of raw materials and finished products.

of warehouse space

a constant supply of components

PVC Material

We process approximately 1,350,000 m² of PVC fabric annually, which is possible not only thanks to our modern production halls and extensive machine park, but also to an efficient supply system. On our premises, we operate consignment warehouses for Serge Ferrari, Heytex, and Dickson, which allows us to maintain a steady stock of high-quality materials and execute orders without delays. In addition, we have built long-standing partnerships with other leading manufacturers such as Sattler, Mehler, Sioen, and Scantarp. These trusted relationships ensure timely deliveries and production stability – even for high-volume orders. We also carry out production using materials supplied by the client.